Airbus is leading aviation innovation with its pioneering HyPower and ZEROe initiatives. These programs aim to revolutionize aircraft efficiency and sustainability by developing hydrogen-powered and hybrid-electric propulsion systems. These ambitious initiatives focus on replacing traditional auxiliary power units (APUs) with cutting-edge hydrogen fuel cells, advancing hybrid-electric propulsion technology, and overcoming the challenges associated with hydrogen storage and infrastructure.

The HyPower demonstrator, spearheaded by Airbus UpNext, is an important step in the company's decarbonization journey. This innovative project seeks to replace the APU of an A330 aircraft with a hydrogen fuel cell system, generating electricity for non-propulsive functions. By utilizing 10kg of gaseous hydrogen sourced from renewable energy, the HyPower demonstrator has the potential to significantly reduce CO2, nitrogen oxides (NOx), and noise emissions associated with conventional APUs. With flight tests scheduled to commence by the end of 2025, the system is designed to operate at altitudes up to 25,000 ft for one hour, showcasing its viability in realistic conditions.

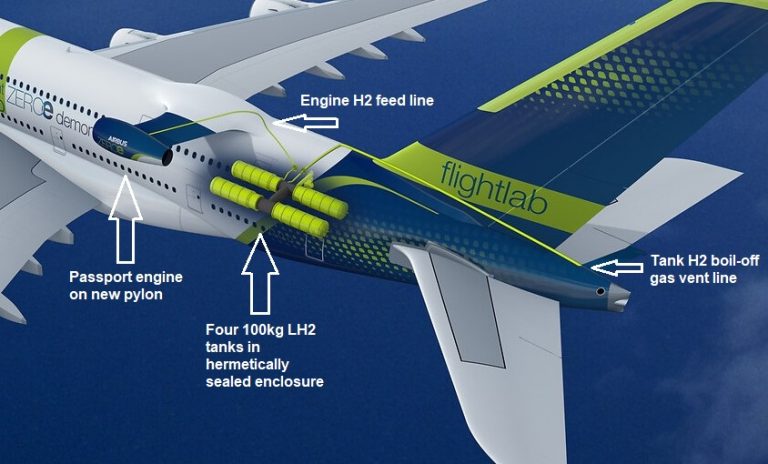

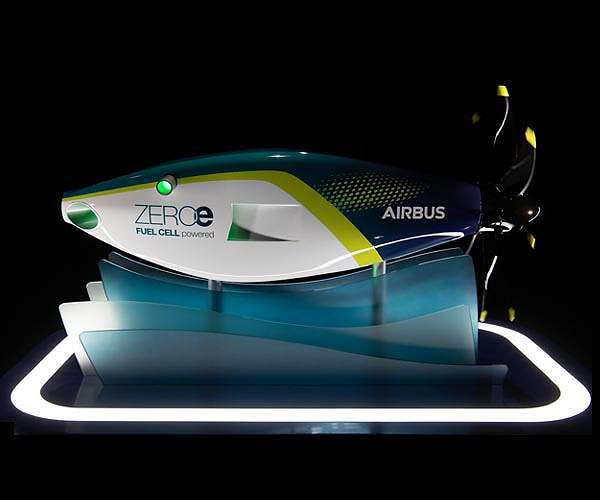

Airbus hydrogen-powered zero-emission engine

Airbus hydrogen-powered zero-emission engine

The HyPower demonstrator is just one facet of Airbus' broader ZEROe program, encompassing a range of hydrogen-powered aircraft concepts. In November 2022, the company celebrated a significant milestone by unveiling its hydrogen fuel cell-powered engine, marking a major step forward in pursuing zero-emission flight. This innovative engine is integral to Airbus' efforts to develop a hybrid-electric propulsion system that seamlessly combines hydrogen fuel cells with conventional aircraft engines.

To support these groundbreaking initiatives, Airbus is heavily investing in critical technologies such as cryogenic tanks for storing liquid hydrogen and fuel cell systems capable of generating megawatt-level power. The company is also exploring various aircraft configurations, including blended-wing body designs, to optimize the integration of hydrogen propulsion systems. However, the development of these technologies is not without its challenges. Improving the energy density of fuel cell systems, ensuring the safe storage and distribution of hydrogen on board, and developing the necessary ground infrastructure for hydrogen refueling are just a few of the hurdles that must be overcome. Despite these obstacles, Airbus remains dedicated to bringing a zero-emission commercial aircraft to market by 2035.

The key to success for these ambitious programs is Collaboration. Airbus is working hand in hand with engine manufacturers, energy companies, and regulatory bodies to tackle the technical, logistical, and regulatory challenges associated with hydrogen-powered flights. The company is also leveraging synergies with other industries, such as the automotive sector, to accelerate the development of key enabling technologies.

As the HyPower and ZEROe programs progress, they are expected to yield significant advancements in fuel cell technology, hydrogen storage solutions, and electric propulsion systems. These innovations can potentially transform commercial aviation and other aerospace industry sectors, including urban air mobility and regional air transport.

Hybrid-electric propulsion systems for aircraft offer several advantages over traditional combustion engines and all-electric systems. Hybrid-electric systems enable more flexible power management by combining two or more power sources, typically a conventional gas turbine or internal combustion engine, with electric motors and batteries. This allows for optimizing energy usage by leveraging the strengths of both electric and combustion power. For example, electric motors can provide additional power during high-demand phases like takeoff, while combustion engines can maintain cruise efficiency.

Hybrid-electric propulsion also will reduce fuel consumption and emissions. By utilizing electric power during specific flight phases, such as taxiing or descent, hybrid systems can minimize the use of combustion engines, leading to fuel savings of up to 5% compared to conventional aircraft. Likewise, hybrid-electric systems can significantly reduce overall emissions compared to conventional aircraft, with the extent of reduction depending on the specific hybrid architecture and operational profile.

Integrating electric motors in hybrid-electric propulsion enables innovative aircraft designs, such as distributed propulsion architectures, where multiple smaller propulsors are spread across the airframe. This approach can improve aerodynamic efficiency and reduce noise compared to centralized engine configurations. Additionally, some hybrid-electric systems can recapture energy during descent or braking, storing it in batteries for later use – a feature impossible with conventional combustion engines.

While hybrid-electric propulsion offers numerous benefits, it also presents some challenges. These systems are generally more complex than pure combustion or electric systems, requiring sophisticated power management and control systems to optimize performance. Including batteries and electric components may also add weight to the aircraft, potentially impacting range or payload capacity and necessitating careful design optimization.

Hydrogen fuel cells, another promising technology being explored by Airbus, offer several advantages over traditional APUs. Fuel cells can significantly reduce fuel consumption and operating costs with up to 60% electrical efficiencies compared to 30-40% for conventional APUs. Moreover, hydrogen fuel cells produce only water vapor as a byproduct, eliminating the CO2, NOx, and particulate emissions associated with combustion-based APUs, aligning with the aviation industry's decarbonization goals.

Fuel cells operate much more quietly than gas turbine APUs, potentially reducing airport noise pollution. Their scalability allows for easier adaptation to meet varying power demands, from small regional aircraft to large commercial airliners. However, the widespread adoption of hydrogen fuel cells will face challenges such as lower energy density than jet fuel, significant investment in hydrogen production, storage, and distribution infrastructure at airports, and developing proper safety protocols for handling and storing hydrogen on aircraft.

These advancements in electric and hybrid-electric propulsion technologies are poised to profoundly impact the emerging field of Advanced Air Mobility (AAM). These technologies enable new aircraft designs and operational concepts that could revolutionize short-range air transportation, offering reduced emissions, lower noise levels, improved efficiency, and simplified maintenance compared to conventional aircraft.

Airbus NextGen eVTOL

Airbus NextGen eVTOL

The advantages of electric and hybrid-electric propulsion are driving the development of various AAM vehicle concepts, including electric vertical takeoff and landing (eVTOL) aircraft for urban air mobility applications, electric or hybrid-electric short takeoff and landing (eSTOL) aircraft for regional transportation, and electric conventional takeoff and landing (eCTOL) aircraft for short-range commuter flights.

However, integrating electric and hybrid-electric propulsion into AAM faces several challenges. Current battery energy densities limit fully electric aircraft's range and payload capacity, necessitating advancements in battery technology, such as solid-state batteries. Widespread adoption of electric AAM will require significant investment in charging infrastructure at vertiports and airports. Regulatory bodies are working to develop certification standards for electric and hybrid-electric aircraft, which is essential for ensuring safety and public acceptance. Also, integrating numerous AAM vehicles into existing airspace will require advanced air traffic management systems capable of handling increased traffic density and diverse aircraft types.

As Airbus continues to push the boundaries of aviation technology with its HyPower and ZEROe programs, the potential for hydrogen-powered and hybrid-electric propulsion to transform the industry is becoming increasingly evident. Through collaboration, innovation, and a steadfast commitment to sustainability, Airbus is paving the way for a cleaner, quieter, and more efficient future of flight.