The introduction of NASA’s sulfur selenium solid-state battery is a game-changer in the quest for sustainable aviation. This innovation, spearheaded by the agency’s Solid-state Architecture Batteries for Enhanced Rechargeability and Safety (SABERS) project, addresses critical challenges in energy storage, safety, and performance for electric aircraft. By redefining the capabilities of battery technology, this breakthrough can accelerate the adoption of Advanced Air Mobility (AAM) and electric vertical takeoff and landing (eVTOL) systems.

Current Limitations of Lithium-Ion Batteries in Aviation

While lithium-ion batteries have served as the foundational energy storage solution for consumer electronics and electric vehicles, their adoption in aviation, particularly for electric vertical takeoff and landing (eVTOL) aircraft, faces critical barriers. Chief among these is their limited energy density of 250 Wh/kg, which falls drastically short of the 800 Wh/kg threshold required for viable electric aircraft operations, constraining flight range and payload capacity. Safety concerns further complicate their use, as flammable liquid electrolytes pose fire risks during high-stress scenarios like rapid discharge or physical damage.

Thermal management presents another hurdle, with complex cooling systems adding weight and eroding efficiency. Compounding these issues, the necessity for heavy protective casings around individual cells undermines the energy-to-weight ratio, a pivotal metric in aerospace design. These limitations have impeded the transition to all-electric aviation, underscoring the urgent need for next-generation energy storage solutions.

NASA’s Sulfur Selenium Solid-State Battery: Technical Breakthroughs

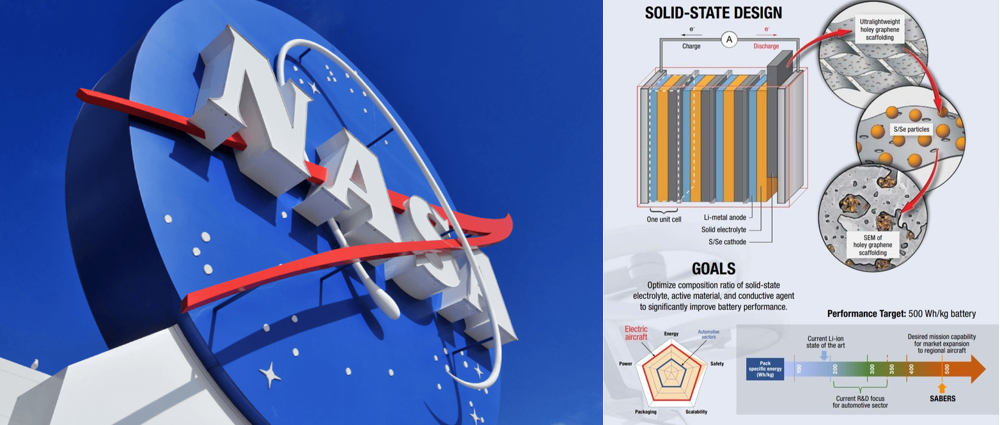

The SABERS team has developed a prototype solid-state battery with an energy density of 500 Wh/kg, doubling the performance of conventional lithium-ion batteries. This leap is achieved through a novel combination of sulfur and selenium in the cathode, paired with a lithium-metal anode. Sulfur, a byproduct of oil refining, is abundant and cost-effective, while selenium enhances electrical conductivity and stability.

By eliminating liquid electrolytes, the sulfur selenium battery inherently reduces fire risks. Testing has demonstrated that the cells maintain structural integrity even when punctured or deformed, a critical feature for aviation safety. Additionally, the battery operates effectively at temperatures up to twice as high as its lithium-ion counterparts, reducing dependence on bulky cooling systems.

The SABERS battery incorporates a “stackable” architecture, where cells are layered without individual casings. This design reduces weight by 40% compared to traditional configurations, increasing energy storage capacity within the same volume. Using “holey graphene,” a lightweight, porous material developed by NASA, further enhances conductivity and reduces mass.

The battery’s discharge rate has been optimized to be 10 times faster than earlier solid-state designs, enabling the high power output required for vertical takeoff and climb phases. This addresses one of the most demanding aspects of eVTOL operations, where rapid energy release is essential.

Implications for the eVTOL Industry

The increased energy density of NASA’s battery directly translates to more extended flight ranges for eVTOL aircraft. For example, with the new technology, a typical eVTOL air taxi like Archer Aviation’s Midnight, which currently has a range of ~100 miles, could see this extended to 200+ miles. This expansion enables intercity routes and reduces the need for frequent recharging, enhancing operational efficiency.

The non-flammable nature of solid-state batteries mitigates one of the foremost concerns for urban air mobility: the risk of battery fires in densely populated areas. This safety assurance is vital for regulatory approval and public acceptance, notably as cities like Los Angeles, Shenzen, and Dubai plan to integrate eVTOLs into their transportation ecosystems.

The sulfur selenium battery’s reduced weight and modularity allow aircraft designers to reallocate space and payload capacity. For instance, Archer’s Midnight utilizes six independent battery packs to power 12 rotors; lighter batteries could enable additional passenger seats or cargo space without compromising flight performance.

Economic Impact: Cost Reductions and Scalability

The sulfur selenium solid-state battery represents a substantial leap in energy storage technology, with deep implications for the economic viability of electric aircraft. This innovation is poised to reshape cost structures across the Advanced Air Mobility (AAM) and electric vertical takeoff and landing (eVTOL) by addressing critical limitations of traditional lithium-ion batteries, particularly energy density, safety, and weight.

Solid-state battery production costs remain high, estimated at $300–500/kWh due to novel materials like holey graphene and selenium. However, NASA’s partnerships with Georgia Tech and Argonne National Laboratory aim to refine scalable manufacturing processes. By 2035, economies of scale could drive costs down to $80–120/kWh, aligning with the Department of Energy’s targets for aviation-grade batteries.

| Battery Type | 2025 Estimate | 2035 Projection |

| Lithium-Ion | $150–$200 | $100–$130 |

| Sulfur Selenium (NASA) | $300–$500 | $80–$120 |

Data synthesized from SABERS project reports and Rho Motion analysis.

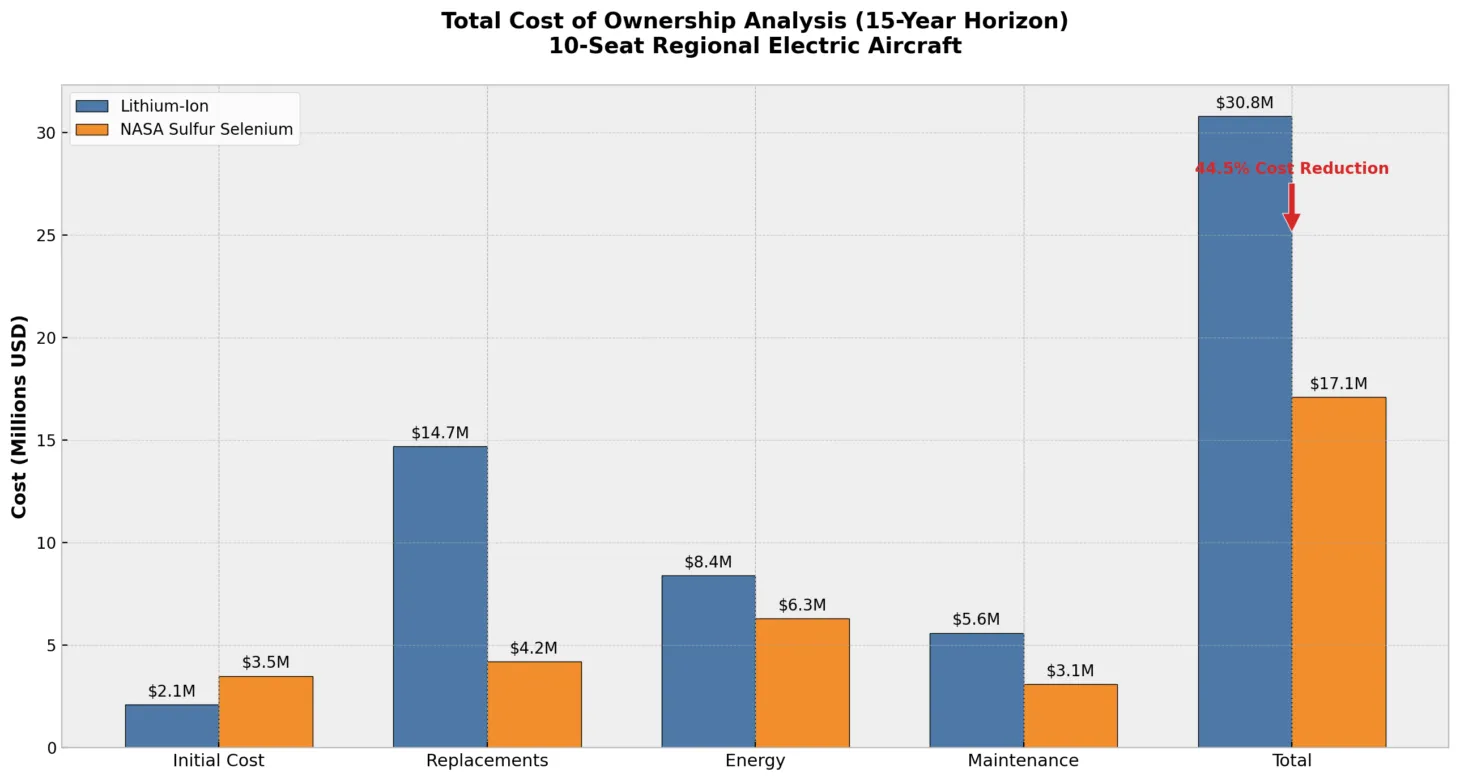

A 2024 study by Rho Motion modeled the TCO for a 10-seat regional electric aircraft over a 15-year lifespan:

Assumptions: 500,000 flight miles, $0.12/kWh energy cost, and 2030 battery prices.

The 44.5% TCO reduction underscores the long-term economic viability of sulfur selenium batteries despite higher upfront costs.

Weight Savings, Range Extension, and Thermal Efficiencydouble

NASA’s sulfur selenium battery delivers performance gains through its 500 Wh/kg energy density, that of conventional lithium-ion batteries, while achieving 40% weight reduction via two design innovations.

- Eliminating individual cell casings enables a stackable architecture that reduces structural mass, while holey graphene, an ultra-lightweight conductive material, optimizes the energy-to-weight ratio. For eVTOL aircraft like Archer Aviation’s Midnight, this means halving the number of battery packs (from six to three) while maintaining a 200+ mile range, slashing upfront material costs by 30–40%. The extended range reduces energy consumption per mile and unlocks revenue potential through additional payload capacity (passengers or cargo), which is critical for air taxi profitability.

- Thermal management is simultaneously streamlined: the solid-state design operates safely at twice the temperature of lithium-ion systems, eliminating bulky liquid cooling infrastructure and reducing associated energy demands by 15–20%. These advancements position sulfur selenium batteries as a cornerstone technology for economically viable, high-performance eVTOL operations.

Safety-Driven Cost Advantages

The non-flammable nature of solid-state batteries eliminates fire risks associated with liquid electrolytes, a leading concern for aviation insurers. Due to reduced liability exposure, industry analysts suggest electric aircraft using sulfur selenium batteries could see insurance premiums 20–30% lower than those for lithium-ion-powered counterparts. Sulfur, a primary cathode material, is a petroleum refining byproduct, making it abundant and low-cost ($0.25–$0.50/kg). NASA’s design emphasizes recyclability, with recovery processes for lithium and selenium under development. Closed-loop recycling could reduce raw material procurement costs by 40–60% over the battery’s lifecycle.

Solid-state batteries exhibit slower degradation rates compared to lithium-ion cells. While precise lifespan data remains proprietary, NASA’s testing indicates 50% less capacity loss after 1,000 charge cycles. An eVTOL performing 10 flights daily equates to a 3–4-year battery lifespan versus 1–2 years for lithium-ion, cutting replacement costs by half over the aircraft’s service life.

Streamlined Certification and Regulatory Costs

The Federal Aviation Administration (FAA) mandates rigorous safety testing for aviation batteries, costing manufacturers $10–$15 million per battery type. NASA’s collaboration with the FAA through the Convergent Aeronautics Solutions (CAS) initiative aims to pre-certify sulfur selenium technology, potentially slashing certification timelines by 30–50% and reducing associated expenses.

The European Union Aviation Safety Agency (EASA) and the International Civil Aviation Organization (ICAO) are developing unified standards for solid-state batteries in aviation. Harmonized regulations will prevent redundant testing across markets, saving manufacturers an estimated $20–$30 million annually in compliance costs.

Addressing Material and Manufacturing Challenges Through Strategic Partnerships

While NASA’s sulfur selenium battery technology presents transformative potential, short-term challenges include material sourcing and production scaling. Selenium, a critical cathode component, remains scarce, with current prices hovering around $30/kg due to limited mining infrastructure and reliance on Chinese supply chains (70% global production). Concurrently, establishing gigafactories for mass production demands $2–5 billion in capital investment, a significant barrier for emerging manufacturers.

To address these hurdles, NASA has forged strategic partnerships: Archer Aviation is co-developing high-volume manufacturing techniques, targeting a 22% cost reduction by 2026 through automated electrode deposition and selenium recovery systems. Meanwhile, Beta Technologies is validating operational models through cargo eVTOL trials, optimizing battery integration for diverse payload configurations. These collaborations aim to de-risk supply chains, demonstrate scalable production, and accelerate FAA/EASA certification, key steps toward commercial viability in the AAM sector.

Sustainability and Environmental Impact

Sulfur selenium batteries could reduce the aviation sector’s carbon footprint by replacing fossil fuel-dependent engines. NASA estimates that commercial aviation accounts for 3% of U.S. greenhouse gas emissions; widespread adoption of electric propulsion could significantly lower this figure. Moreover, sulfur (a petroleum byproduct) promotes circular economy principles by repurposing waste materials.

Collaboration with Industry Leaders

NASA’s partnerships with companies like Archer Aviation, Joby Aviation, and Beta Technologies are critical to translating laboratory breakthroughs into commercial solutions. Under a Space Act Agreement, Archer is testing its battery systems at the European Synchrotron Radiation Facility (ESRF), using high-speed X-rays to analyze performance under extreme conditions. These collaborations aim to establish standardized safety and performance benchmarks for the AAM industry.

Future Prospects and Broader Applications

The SABERS technology is not limited to urban air taxis. NASA envisions applications in regional electric aircraft, such as hybrid-electric commuter planes, which could reduce emissions on short-haul routes. The battery’s resilience to extreme temperatures and radiation makes it a candidate for space missions, including lunar rovers and Mars helicopters. Ongoing research into “holey graphene” and alternative cathode materials (e.g., lithium-sulfur composites) promises further energy density and cycle life gains. The SABERS team also investigates solid-state electrolytes with higher ionic conductivity to enhance charge/discharge rates.

By doubling energy density to 500 Wh/kg and eliminating flammable electrolytes, the technology unlocks new possibilities for eVTOL and Advanced Air Mobility (AAM) systems, from extended flight ranges to safer urban operations. Economically, it promises cascading cost benefits: a 44.5% reduction in total ownership costs, 20–30% lower insurance premiums, and the potential to narrow the price gap between electric and fossil-fueled aircraft by 60–70% by 2035.

While challenges persist in certification, material sourcing, and infrastructure scaling, collaborative efforts between NASA, regulators, and industry leaders like Archer Aviation and Beta Technologies are accelerating commercialization. As manufacturing scales and recycling protocols mature, sulfur selenium batteries are the cornerstone of sustainable aviation. This new technology points to a future where electric aircraft dominate urban skies and regional routes, transforming air mobility into a clean and accessible mode of 21st-century transportation.