Low-Altitude Economy | Urban Air Mobility | eVTOL | Low Altitude Mobility

ZeroAvia’s Electric Propulsion System Powers Jetcruzer 500E

ZeroAvia’s innovative 600 kW electric propulsion system (EPS) has found its first customer in Jetcruzer International, marking a significant step in commercializing hydrogen-electric aviation. This partnership aims to integrate ZeroAvia’s technology into the Jetcruzer 500E, a six-seat hydrogen-electric aircraft targeting entry into service by 2028.

ZeroAvia’s 600 kW Electric Propulsion System

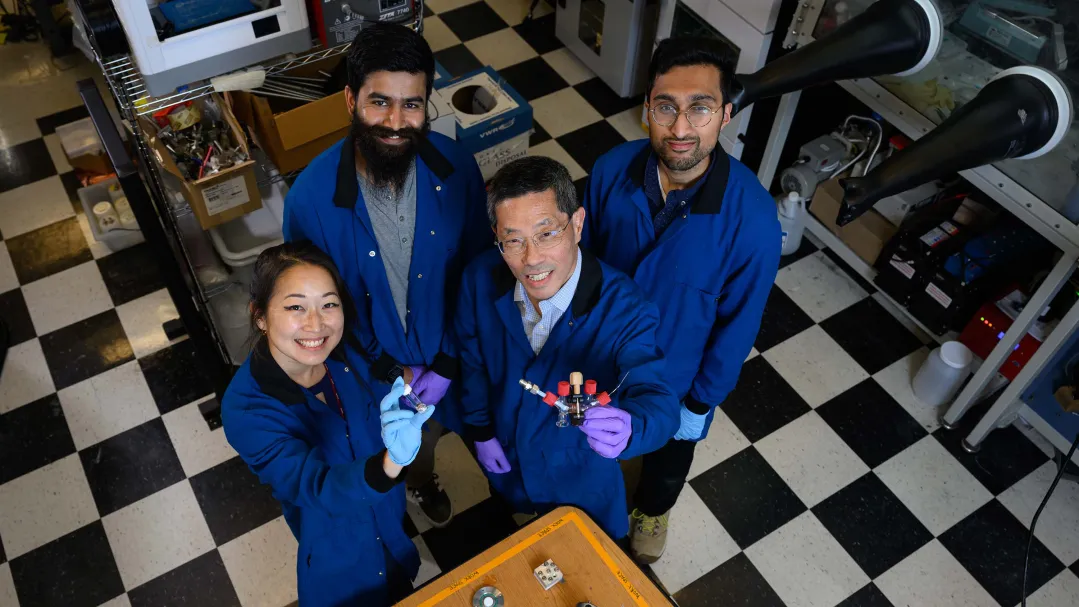

600-kilowatt electric propulsion system (EPS) from ZeroAvia

600-kilowatt electric propulsion system (EPS) from ZeroAvia

ZeroAvia’s EPS is a modular system designed for efficiency and adaptability. The system features:

- Four 200 kW bidirectional inverters convert DC power to AC for a direct-drive motor.

- A motor capable of reaching 2,200 rpm, optimized for high-torque aviation demands.

- Bidirectional energy recovery capabilities, which enhance efficiency during descent or braking.

The EPS forms the core of ZeroAvia’s ZA600 powertrain, designed for retrofitting into existing 19-seat aircraft like the Cessna Caravan. ZeroAvia has created a standalone product line that serves both hybrid and fully electric aircraft developers by decoupling the electric propulsion components from their hydrogen fuel cell systems. This strategic move broadens market applicability, positioning ZeroAvia as a tier-one supplier for emerging electric vertical takeoff and landing (eVTOL) and fixed-wing OEMs.

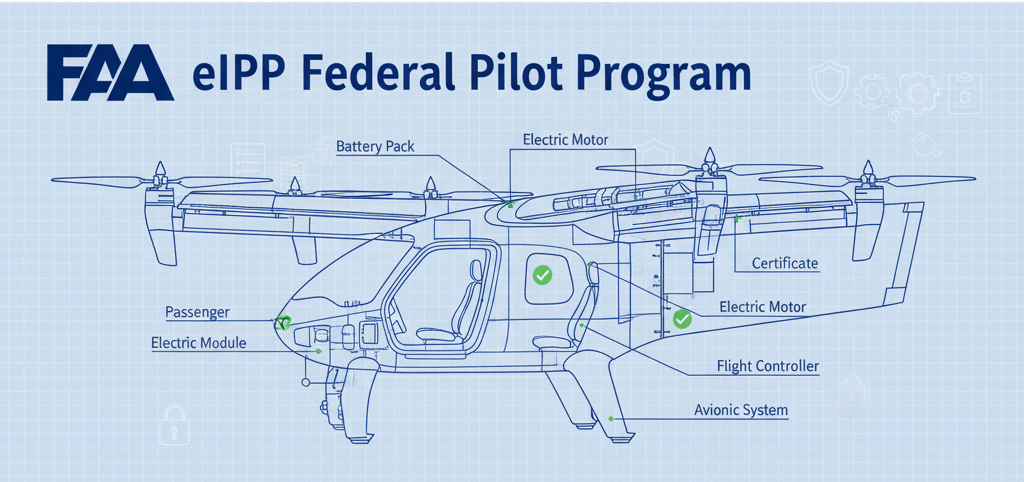

Certification Progress and Regulatory Compliance

A pivotal achievement for the 600 kW EPS is its recent receipt of an FAA G-1 issue paper, which outlines the certification basis for the system under Part 33 regulations. This milestone accelerates Jetcruzer’s path to flight testing, as the G-1 paper provides a regulatory framework for addressing airworthiness requirements, including thermal management, electromagnetic compatibility, and fault tolerance. ZeroAvia’s decision to pursue component-level certification reflects industry-wide shifts toward modular aircraft systems, enabling faster iteration and scalability across platforms.

Aircraft Specifications

The Jetcruzer 500E revives the 1990s-era Jetcruzer 500, a canard-configured, pusher-prop design originally FAA-certified in 1994 but never produced. Key features include:

- Seating: 6 passengers

- Range: 500 nautical miles (926 km)

- Propulsion: ZeroAvia’s EPS retrofitted into the aft nacelle

- Target Markets: Regional air taxi services and short-haul cargo

The larger 1250E variant, planned for 2030, will feature twin EPS units and liquid hydrogen storage. It is targeted at 10 seats and a transcontinental range.

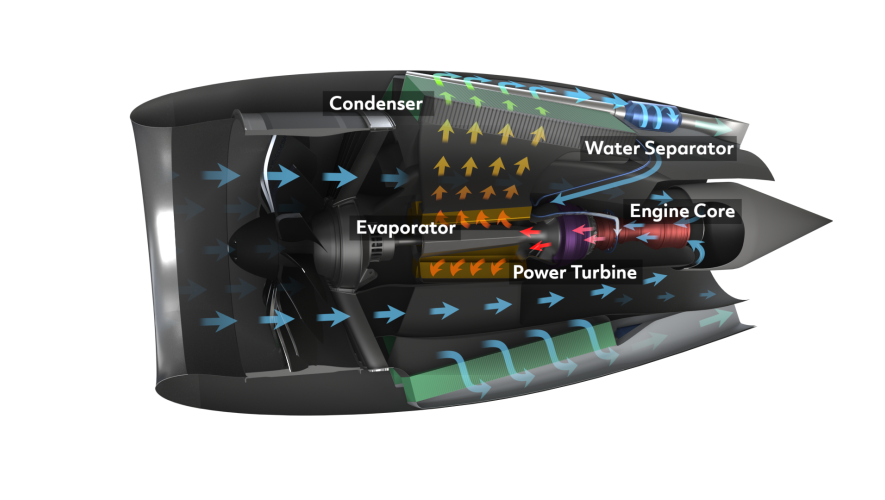

Hydrogen Integration Strategy

Initial flights will use battery packs, transitioning to hydrogen fuel cells as storage technology matures. This phased approach minimizes redesign costs while awaiting advancements in cryogenic hydrogen tanks.

Historical Context: The Jetcruzer’s Revival

Developed initially by Advanced Aerodynamics and Structures (AASI), the Jetcruzer 500 leveraged composite materials and a low-drag canard design for fuel efficiency. Despite FAA certification, production halted due to financial constraints until Jetcruzer International acquired the IP in 2017. Electrifying this platform reduces development risks by utilizing proven aerodynamics, aligning with industry trends toward legacy fleet modernization.

Key Competitors: MagniX and Emerging Players

ZeroAvia faces robust competition from MagniX, whose 650 kW magni650 propulsion unit powers projects like Harbour Air’s electric DHC-2 Beaver. However, ZeroAvia’s bidirectional inverter technology and vertical integration provide distinct advantages in fault tolerance and energy recovery35. Unlike MagniX’s focus on battery-electric systems, ZeroAvia’s hydrogen-electric roadmap positions it for longer-range applications as fuel cell densities improve.

| Company | Technology | Key Projects |

|---|---|---|

| MagniX | 650 kW magni650 propulsion unit | Retrofit solutions for regional aircraft |

| Universal Hydrogen | Hydrogen fuel cell conversions | Dash 8-300 conversions targeting 2025 |

| Joby Aviation | Hydrogen-EVTOL integration | 523-mile flight using hydrogen fuel cells |

| Airbus | Hydrogen infrastructure studies | Scandinavian airport feasibility assessments |

ZeroAvia’s vertical integration, producing in-house inverters, motors, and fuel cells, provides a competitive edge in efficiency and cost. With over 2,000 pre-orders, primarily from regional airlines, ZeroAvia aims to convert these into firm contracts after the 500E flight tests.

Market Differentiation and Strategic Positioning

ZeroAvia’s 2,000+ pre-orders, primarily from regional airlines, underscore market confidence in its ZA600 powertrain. The company’s Propulsion Center of Excellence in Everett, Washington, enables simultaneous production of proprietary components and third-party systems, creating diversified revenue streams. This vertical integration contrasts with competitors like Heart Aerospace and Ampaire, which rely on external suppliers for critical subsystems.

Synergies Between ZeroAvia and Jetcruzer

The partnership exemplifies a symbiotic relationship between propulsion specialists and airframe developers. ZeroAvia gains a real-world testbed for its EPS, enabling data collection on thermal performance, vibration profiles, and maintenance requirements. Conversely, Jetcruzer leverages ZeroAvia’s certification progress to accelerate its timeline, avoiding the R&D costs associated with developing propulsion systems in-house. Sergey Kiselev, ZeroAvia’s Chief Business Officer, emphasizes that this collaboration validates the company’s component strategy, which unlocks revenue streams beyond complete powertrain sales.

Broader Implications for Advanced Air Mobility

This deal signals a maturation of the AAM sector, moving from conceptual designs to hardware-in-the-loop testing. The FAA’s engagement in certifying the EPS underscores regulatory agencies’ growing familiarity with electric propulsion, setting precedents for future systems. Moreover, Jetcruzer’s focus on retrofitting existing aircraft provides a blueprint for decarbonizing legacy fleets—a critical consideration given the long service lives of commercial aviation.

Technical Hurdles in Hydrogen-Electric Integration

While the EPS is nearing certification, integrating it with hydrogen fuel cells presents lingering challenges. Current fuel cell stacks face power density limitations, requiring innovative cooling solutions to manage heat rejection during high-thrust maneuvers. Additionally, hydrogen storage remains a bottleneck, with composite pressure vessels adding weight that offsets the efficiency gains of electric propulsion. ZeroAvia’s parallel development of high-temperature PEM fuel cells aims to address these issues, but widespread adoption hinges on breakthroughs in materials science.

Conclusion

The ZeroAvia-Jetcruzer partnership bridges historical engineering with cutting-edge propulsion, offering a blueprint for sustainable regional air mobility. By retrofitting the Jetcruzer 500E with ZeroAvia’s EPS, this initiative accelerates the transition to zero-emission flight while mitigating development risks. As hydrogen storage and fuel cell technologies advance, such collaborations will likely define the next decade of aviation innovation, balancing environmental goals with operational practicality.