MIT researchers have achieved a breakthrough that could transform electric aviation and boost the growth of the low-altitude economy. Their new sodium-air fuel cell technology delivers more than three times the energy density of current lithium-ion batteries, potentially providing the power breakthrough needed to make regional electric flight practical at a commercial scale.

The implications for the rapidly expanding low-altitude economy are significant. This emerging economic sector includes activities conducted below 1,000 meters, although operations can reach up to 3,000-4,000 meters, depending on the specific application. With China already dominating the space through 70% of global eVTOL patents and over 50,000 related enterprises, breakthrough energy storage technologies like  MIT’s sodium fuel cell could reshape competitive dynamics worldwide.

MIT’s sodium fuel cell could reshape competitive dynamics worldwide.

Triple the Power, Half the Wait

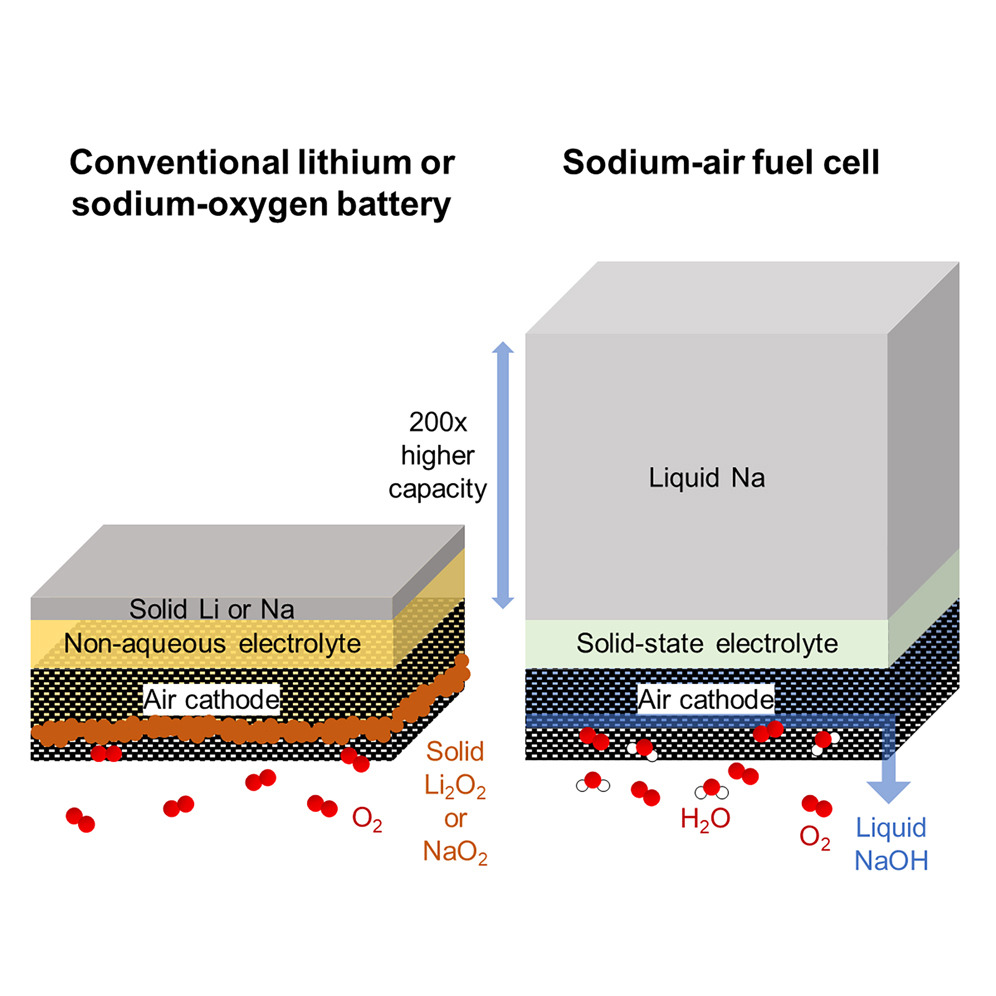

The sodium-air fuel cell achieves energy densities exceeding 1,000 watt-hours per kilogram at the system level, compared to just 300 watt-hours per kilogram for today’s best lithium-ion batteries. Professor Yet-Ming Chiang of MIT describes 1,000 watt-hours per kilogram as the recognized threshold needed to electrify aviation and other hard-to-decarbonize transport sectors.

This breakthrough addresses the fundamental challenge that has long plagued electric aviation. Current battery limitations have constrained aircraft like Eviation’s Alice to 250-mile ranges, forcing companies to reduce their projected specifications. Wright Electric has been pursuing its own high-temperature molten battery technology, targeting similar energy densities of 1,000 watt-hours per kilogram. However, MIT’s approach offers distinct advantages.

Unlike traditional batteries that require recharging, the sodium fuel cell can be quickly refueled with liquid sodium metal cartridges. The system operates by reacting liquid sodium with oxygen from humidified air, creating electricity while producing sodium hydroxide as a byproduct. The liquid sodium melts at just 98 degrees Celsius, making refueling relatively straightforward.

When Airplane Exhaust Actually Cleans the Air

The MIT fuel cell offers environmental advantages that extend beyond zero carbon emissions. The sodium hydroxide byproduct naturally captures carbon dioxide from the atmosphere, forming sodium carbonate, which eventually decomposes into sodium bicarbonate (baking soda). When this material reaches the ocean, it could help counter acidification caused by greenhouse gases.

Professor Chiang explains that using sodium hydroxide for carbon capture has been proposed before, but was economically unfeasible due to the compound’s high cost. However, when it’s a byproduct of energy generation, it provides environmental benefits at no additional cost.

This carbon-negative potential distinguishes MIT’s technology from hydrogen fuel cell alternatives being pursued by companies such as Airbus and ZeroAvia. While hydrogen produces only water vapor as exhaust, it requires complex cryogenic storage systems and pressurized infrastructure that add weight and complexity.

Why Molten Salt Beats Exploding Batteries

The fuel cell design offers inherent safety benefits over traditional batteries. With one side containing liquid sodium and the other just diluted air, the risk of catastrophic runaway reactions is significantly reduced compared to batteries with two concentrated reactants adjacent to each other. This safety profile becomes critical as energy densities increase.

MIT’s research team has already formed Propel Aero to commercialize the technology, housed in MIT’s startup incubator, The Engine. The company plans to demonstrate a brick-sized fuel cell capable of powering large drones within the next year, initially targeting agricultural applications before scaling to larger aircraft.

The abundance of sodium offers another advantage. Unlike lithium, which faces supply chain constraints, sodium is readily available in common salt and can be produced on a massive scale. Historical production of sodium metal reached 200,000 tons annually in the United States for leaded gasoline production, demonstrating the feasibility of large-scale manufacturing and distribution.

The New Battery Wars: Sodium vs. Hydrogen vs. Solid State

SiCore cells powered AALTO’s Zephyr aircraft during a record-setting 67-day stratospheric flight

SiCore cells powered AALTO’s Zephyr aircraft during a record-setting 67-day stratospheric flight

The electric aviation battery market is fiercely competitive, with several technology paths emerging. Amprius Technologies has secured significant contracts for its silicon anode batteries, including a $35 million order from a leading manufacturer of unmanned aerial systems. The company’s SiCore cells powered AALTO’s Zephyr aircraft during a record-setting 67-day stratospheric flight, demonstrating the potential of advanced lithium-ion technologies.

NASA’s SABERS project has developed sulfur-selenium solid-state batteries, achieving 500 watt-hours per kilogram while eliminating fire risks. These batteries operate at temperatures twice as high as those of their lithium-ion counterparts and feature a stackable architecture that reduces weight by 40%. However, they still fall short of the 1,000 watt-hours per kilogram threshold that MIT’s fuel cell surpasses.

Hydrogen fuel cell technology represents another competing approach. Airbus has committed to hydrogen fuel cells for its ZEROe aircraft program, partnering with MTU Aero Engines to develop commercial applications by 2035. ZeroAvia continues advancing its hydrogen-electric powertrains for 10-20 seat and 40-80 seat regional aircraft. While hydrogen offers excellent energy density, it requires sophisticated storage and handling infrastructure that adds complexity and cost.

Wright Battery

Wright Battery

Wright Electric has taken a unique approach with high-temperature molten lithium-sulfur batteries targeting 800-1,000 watt-hours per kilogram. The company received a $3.34 million FAA FAST program award to develop batteries capable of enabling electric aircraft with 100+ passenger capacity. However, thermal management of molten batteries presents significant engineering challenges.

Impact on Low-Altitude Economy Development

The low-altitude economy represents a transformative shift in transportation, logistics, and urban mobility. Current operations heavily rely on battery-powered eVTOL aircraft, which have limited range and payload capabilities. Companies like EHang have achieved full regulatory certification in China for passenger operations; however, their EH216-S aircraft has a 25-minute flight time and a 35-kilometer range.

MIT’s sodium fuel cell technology could dramatically expand operational capabilities. Regional electric aviation accounts for approximately 80% of domestic flights and 30% of aviation emissions, making it a prime target for electrification. Current eVTOL manufacturers, such as Heart Aerospace, have scaled back from the 19-passenger ES-19 aircraft to hybrid-electric ES-30 configurations due to battery limitations. Advanced energy storage could enable pure electric operation for larger aircraft and longer routes.

The vertiport infrastructure market is expected to surge from $0.4 billion in 2023 to $10.7 billion by 2030, but current plans assume limited aircraft capabilities. Higher energy density storage could support more ambitious route networks and reduce the number of vertiports needed for regional connectivity.

Urban air mobility operations currently face significant constraints from battery weight and charging requirements. The Alice aircraft from Eviation requires 30 minutes of charging for every hour of flight time, which limits operational efficiency. Sodium fuel cell refueling could occur as quickly as conventional aircraft refueling, dramatically improving aircraft utilization rates.

Building Tomorrow’s Aviation Fuel Network”

The FAA has been actively preparing for advanced air mobility operations, issuing comprehensive regulations for powered-lift aircraft operations in 2024. The agency’s Urban Air Mobility Concept of Operations outlines frameworks for integrating eVTOL aircraft into the National Airspace System. However, current regulations assume battery-powered aircraft with limited capabilities.

Fuel cell aircraft would require different infrastructure and operational procedures. Instead of electrical charging stations at vertiports, operators would need sodium fuel storage and handling systems. The relatively simple thermal requirements for liquid sodium (heated to 98 degrees Celsius) could simplify infrastructure compared to those of hydrogen, which have cryogenic needs.

The FAA has developed vertiport design standards, as outlined in Engineering Brief 105A, with a focus on eVTOL aircraft with maximum takeoff weights of 12,500 pounds. Higher energy density storage could enable larger aircraft requiring updated infrastructure standards and operational procedures.

The Bumpy Road from Lab Bench to Passenger Seat

Despite its promise, MIT’s sodium fuel cell technology faces significant challenges in its development. The current prototype exists only at a laboratory scale, requiring substantial engineering to achieve commercial viability. Propel Aero aims to demonstrate an extensive drone application within a year, but passenger aircraft applications remain years away.

Thermal management represents a critical challenge. Operating with molten sodium at nearly 100 degrees Celsius requires careful engineering to ensure safe, reliable operation under aviation conditions. Wright Electric faces similar challenges with its high-temperature battery technology.

Power density remains a limitation. While the MIT fuel cell achieves excellent energy density, its power density of approximately 40 watts per kilogram is relatively low for aviation applications. This trade-off between energy and power density must be optimized for different aircraft requirements.

The low-altitude economy is developing rapidly, with companies like EHang already conducting commercial operations and multiple manufacturers approaching certification. For MIT’s technology to have maximum impact, development timelines must align with industry needs and regulatory frameworks.

Why This Changes Everything for Aviation

MIT’s sodium-air fuel cell breakthrough represents more than an incremental improvement in battery technology. It offers a potential pathway to efficient electric aviation that could reshape the low-altitude economy. The combination of high energy density, environmental benefits, inherent safety, and abundant fuel supply addresses fundamental challenges that have constrained electric aircraft development.

The technology’s success could accelerate the transition from today’s limited eVTOL operations to comprehensive urban and regional air mobility networks. Rather than requiring extensive ground infrastructure for battery charging, sodium fuel cells could enable aircraft to operate more like conventional aircraft, refueling quickly and maintaining high utilization rates.

For the low-altitude economy, this represents an opportunity to move beyond niche applications toward proper integration with transportation networks. Regional airlines could consider electric aircraft for routes that currently rely on turboprop aircraft. At the same time, cargo operators could electrify their delivery networks without the weight penalties associated with current battery technology.

The competitive implications are equally significant. While China currently leads eVTOL development through coordinated government investment and planning, breakthrough energy storage technologies could level the playing field. American companies with access to advanced fuel cell technology might regain competitive advantages in aircraft performance and operational economics.

As Professor Chiang noted, truly revolutionary ideas initially seem wild. MIT’s sodium fuel cell approach challenges conventional thinking about aviation energy storage, offering a path beyond the limitations that have constrained electric flight. Whether in agricultural drones, urban air taxis, or regional passenger aircraft, this technology could finally deliver on the long-promised potential of electric aviation.