Low-Altitude Economy | Urban Air Mobility | eVTOL | Low Altitude Mobility

Beyond Aero’s BYA-1 Hydrogen Aircraft: Program Update 2025

Beyond Aero has been busy. The French company spent 2025 redesigning its BYA-1 hydrogen aircraft and overcoming certification hurdles that had never been solved before. They’re building what they call the world’s first hydrogen-electric business jet, and frankly, the engineering challenges make rocket science look straightforward. Here’s what happened this year and why it matters for anyone watching the future of flight unfold.

The Big Redesign of March 2025

Beyond Aero has redesigned its BYA-1 hydrogen powered business jet, moving fuel tanks to the wing.

Beyond Aero has redesigned its BYA-1 hydrogen powered business jet, moving fuel tanks to the wing.

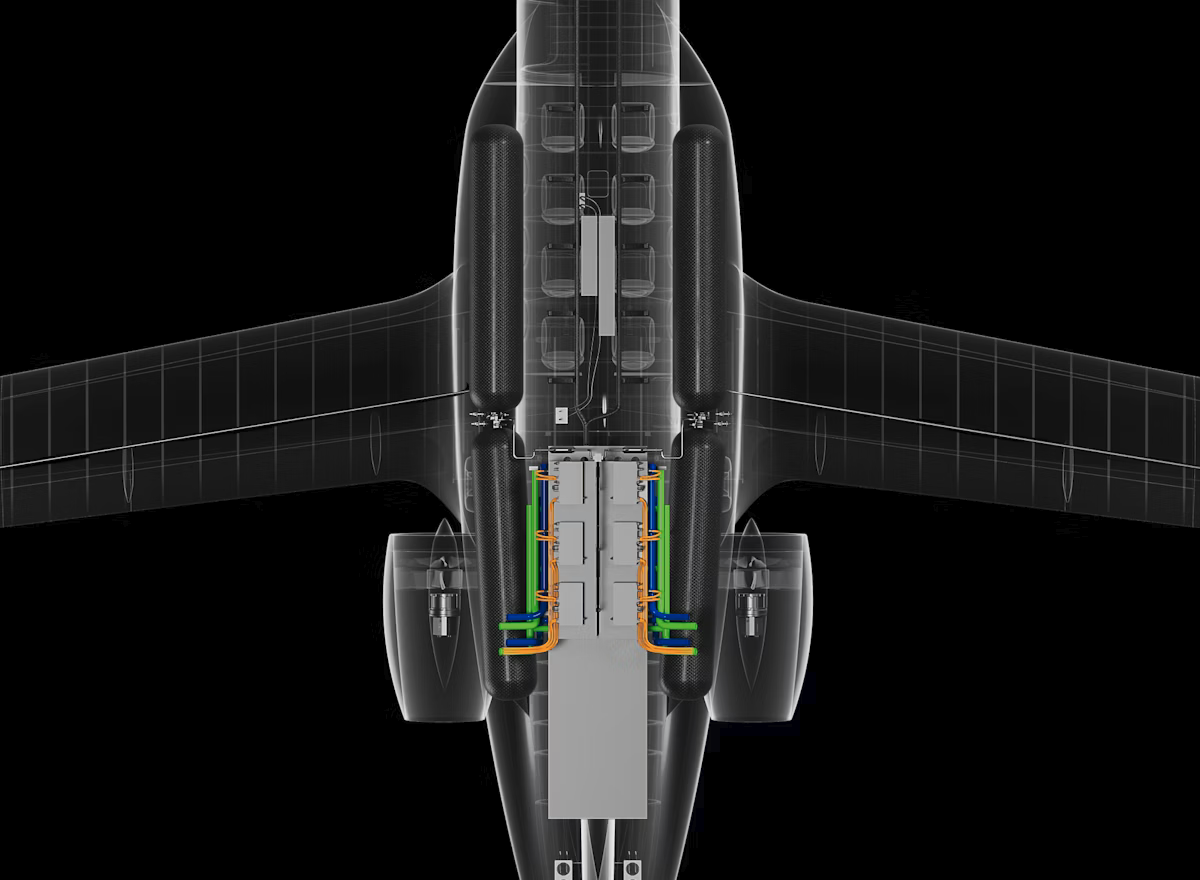

Beyond Aero unveiled its updated BYA-1 design in March, and the changes reveal everything about the reality of hydrogen aviation. The most critical modification involved moving the hydrogen fuel tanks from inside the fuselage to above the wing box. This wasn’t cosmetic tweaking—this was basic physics meeting aviation safety regulations.

Hydrogen gas at pressures exceeding 700 bars presents unique hazards. You can’t run high-pressure fuel lines through a pressurized passenger cabin and expect regulators to sign off on it. The new configuration eliminates this problem while improving crashworthiness; however, it requires a complete rethinking of the aircraft’s structure.

The fuel cell system now produces 2.4 megawatts of power through a modular design that operates without the need for batteries. Two independent electric engines provide redundancy, as backup systems become essential when flying on technology that has never been certified before. A custom-designed Full Authority Digital Engine Control system ensures precise performance across all phases of flight, from takeoff through cruise to landing approach.

Two-seat prototype aircraft in flight

Two-seat prototype aircraft in flight

Beyond Aero tested their approach with France’s first manned hydrogen-electric flight in 2024 using a two-seat prototype. The flight worked. The technology proved viable. Now comes the hard part: scaling it up and convincing regulators it’s safe enough for paying passengers.

What You Get in the BYA-1

The finished aircraft will carry six passengers at a speed of 310 knots for a distance of 800 nautical miles. Those numbers put it directly against the Cessna Citation CJ3 and Embraer Phenom 300, except this version runs on hydrogen and produces zero carbon emissions.

The performance specifications look impressive on paper. A takeoff roll of 1,860 feet means it can operate from constrained airports like London City. The approach angle of 5.5 degrees provides flexibility that turbine-powered competitors can’t match. Cabin noise drops 15 decibels below conventional aircraft through electric propulsion and advanced acoustic treatments.

Operating costs tell the real story. Beyond Aero projects fuel costs 65% lower than sustainable aviation fuels through 2025 and 17% below traditional Jet A-1 by 2030. The electric powertrain reduces moving parts by 90% compared to turbine engines, which should translate into lower maintenance requirements.

The passenger experience receives particular attention, with elliptical windows that are 27% larger than those of conventional business jets. But here’s the catch: these projections assume hydrogen fuel becomes widely available at airports. That assumption carries significant risk.

The Certification Challenge

No one has yet certified a hydrogen-powered passenger aircraft. Beyond Aero submitted their Design Organization Approval to EASA in April 2024 and now works directly with European regulators to establish certification standards that don’t yet exist.

Walter Filho, Beyond Aero’s Head of Certification, frames their situation clearly: “We are setting the precedent for hydrogen-electric certification. Working closely with EASA, we are shaping regulatory pathways that will enable the safe and efficient adoption of hydrogen propulsion in aviation.”

Current CS-23 regulations don’t address hydrogen aircraft. EASA must develop special conditions specifically for Beyond Aero’s technology. This process requires proving that hydrogen systems meet equivalent safety levels to conventional aircraft, which means extensive testing and documentation for every component.

The timeline stretches into the late 2020s. Beyond Aero targets its preliminary design review by the end of 2025, critical design review around 2026, and design freeze in early 2027. The first deliveries are expected to occur in the early 2030s, assuming everything proceeds smoothly.

Who Else Is Racing Toward Hydrogen Flight

Beyond Aero isn’t alone in this pursuit. Several companies chase the same goal using different approaches, and their progress reveals both the promise and limitations of hydrogen aviation.

ZeroAvia leads the certification race with its ZA600 powertrain, which is currently under review by UK regulators. They successfully flew a 19-seat aircraft powered by hydrogen in January 2023 and continue to develop larger systems for regional aircraft seating 40-80 passengers. ZeroAvia recently secured UK government funding and plans to build manufacturing facilities near Glasgow Airport.

Stralis Aircraft in Australia focuses on retrofitting existing aircraft rather than designing new ones. They ground-tested a hydrogen-powered Bonanza in December 2024 and plan flight tests by late 2025. Stralis claims their high-temperature fuel cells are six times lighter than conventional systems while providing ten times the range of battery-electric alternatives.

H2FLY, now owned by Joby Aviation, achieved the world’s first piloted flight using liquid hydrogen in September 2023. Their four-seat HY4 demonstrator proved liquid hydrogen works in aviation, though the cryogenic storage requirements add significant complexity.

Airbus recently reset its entire hydrogen program. The aerospace giant pushed back their ZEROe aircraft from 2035 to the early 2040s while switching from hydrogen combustion to hydrogen fuel cells. This delay sent shockwaves through the industry, slowing airport infrastructure investments.

Market Reality Check

The business jet market provides a logical entry point for hydrogen aviation. These aircraft typically fly shorter routes, where hydrogen’s range limitations matter less, and business aviation customers may be willing to accept higher costs for environmental benefits.

Beyond Aero’s financial momentum continued through 2024, culminating in a $20 million Series A funding round in October 2024, which brought their total capital to over $44 million. Around the same time, they collected $914 million in Letters of Intent for 108 aircraft. These commitments suggest market confidence in their approach, but converting letters of intent into firm orders requires proving the technology works at scale.

Current market projections indicate that hydrogen aviation is expected to grow from $2.7 billion in 2025 to $15 billion by 2034, representing a 21.1% compound annual growth rate. The low-altitude economy presents particular opportunities where shorter flights with frequent operations could optimize fuel cell efficiency while building infrastructure for larger aircraft. Beyond Aero’s specifications align well with urban air mobility missions that form the backbone of emerging aerial transportation networks.

Investment patterns indicate cautious optimism. The hydrogen aviation industry hasn’t converged on optimal technical solutions, with different companies pursuing various approaches to the same fundamental challenges. This diversity suggests the technology remains immature, but it also creates opportunities for breakthrough innovations.

The Reality of Physics and Infrastructure

Now comes the tricky part. Hydrogen aviation faces challenges that extend beyond the scope of engineering solutions. The physics are unforgiving: hydrogen contains less energy per unit volume than conventional jet fuel, even when compressed to 700 bars. This energy density limitation forces aircraft designers into uncomfortable compromises between range, payload, and fuel storage space.

Beyond Aero’s gaseous hydrogen approach sidesteps the complexity of cryogenic liquid systems; however, the trade-off is a reduced range. Their 800-nautical-mile target encompasses most European business aviation routes, yet longer flights necessitate fuel stops that conventional aircraft typically avoid entirely. Fuel cell systems cost substantially more than turbine engines, and while economies of scale should drive prices down, it is unclear when cost parity will be achieved. Early customers will pay premium prices for technology that’s still proving itself.

However, the technical challenges pale in comparison to the infrastructure problem that Airbus’s recent delays have exposed. When the aerospace giant pushed their ZEROe program from 2035 to the early 2040s, major airports immediately scaled back their hydrogen facility investment plans. This created exactly the circular problem the industry feared: aircraft developers need fuel infrastructure to justify their programs, while airports need confirmed aircraft deliveries before they’ll invest in expensive hydrogen systems.

Green hydrogen production remains expensive and limited in scale across multiple industries, not just the aviation sector. If aircraft operators resort to grey hydrogen produced from natural gas, the environmental benefits that justify the entire enterprise disappear. The value proposition hinges on scaling renewable hydrogen production, which necessitates coordinated investment across the energy, transportation, and aviation industries simultaneously.

Airport infrastructure development has slowed following Airbus’s ZEROe delay, with major hubs like Heathrow reducing the urgency of hydrogen facility investments. This creates a chicken-and-egg problem where success depends on factors entirely outside any single company’s control.

What Happens Next

Beyond Aero’s approach appears more realistic than some competitors. Their focus on business aviation avoids the massive infrastructure requirements of commercial airlines while targeting customers willing to pay for environmental benefits. The 2030 timeline assumes favorable outcomes across multiple uncertainties; however, recent industry developments suggest this might be overly optimistic.

The regulatory landscape continues evolving rapidly. EASA has developed dedicated Special Conditions for certifying hydrogen aircraft, working closely with the industry to establish safety frameworks. The FAA released its Hydrogen-Fueled Aircraft Safety and Certification Roadmap in December 2024, outlining plans to address regulatory issues related to hydrogen-fueled aircraft.

Success requires more than technical achievement. It demands coordinated change across aircraft development, fuel production, airport infrastructure, and regulatory frameworks. Beyond Aero participates in this ecosystem rather than controlling it, which makes their ultimate success dependent on industry-wide progress.

The following two years will determine whether Beyond Aero’s approach proves viable. Their preliminary design review, scheduled for completion by the end of 2025, will decide whether their engineering solutions can meet certification requirements. Meanwhile, competitors advance their own programs, and the hydrogen infrastructure develops at its own pace.

You’re watching the early stages of what might become aviation’s next major transition. Or you might be watching an expensive experiment that teaches valuable lessons about the limits of current technology. Either way, Beyond Aero’s progress provides a real-time case study in how new aviation technologies emerge from concept to commercial reality.

The company appears well-positioned within the hydrogen aviation ecosystem, with solid funding, reasonable technical choices, and a targeted market approach. But like everyone else in this space, they’re betting that the infrastructure, regulations, and economics will align in their favor—the physics work. The engineering looks sound. Now comes the test of whether the world is ready for hydrogen flight.

Current BYA-1 Specifications: Comprehensive Data Tables

Beyond Aero’s BYA-1 Hydrogen Aircraft

Beyond Aero’s BYA-1 Hydrogen Aircraft

Aircraft Dimensions and Weight Specifications

| Specification | Metric | Imperial |

| Length | 18.59 m | 61.02 ft |

| Height | 6.13 m | 20.12 ft |

| Wingspan | 17.0 m | 55.8 ft |

| Wing Height | 6.84 m | 22.45 ft |

| Cabin Height | 3.14 m | 10.3 ft |

| Max Take-off Weight | 8,618 kg | 19,000 lb |

| Max Landing Weight | 8,618 kg | 19,000 lb |

| Max Payload | 760 kg | 1,675 lb |

| Hydrogen Tank Capacity | 250 kg GH2 | 551 lb GH2 |

| Baggage Compartment (Volume) | 1.5 m³ | 53.0 ft³ |

| Baggage Compartment (Weight) | 150 kg | 331 lb |

Powerplant and Propulsion Systems

| Component | Specification | Additional Details |

| Fuel Cell System Power | 2,400 kW total | Gaseous hydrogen (GH2) |

| Fuel Cell Configuration | 6 × 400 kW | Redundant powertrain for fail-safety |

| Hydrogen Storage Pressure | 700 bar | High-pressure storage |

| Refueling Time | 30-40 minutes | Standard refueling procedure |

| Propulsion Type | Electrically driven ducted fans | Electric ducted fan propulsion |

| Static Thrust per Fan | 12,500 N | 2,809 lbf per fan |

| Total Static Thrust | 25,000 N | 5,618 lbf total |

| Number of Fans | 2 | Twin-engine configuration |

Performance Specifications

| Parameter | Value |

| Maximum Certified Altitude | 26,000 ft (7,925 m) |

| Cabin Altitude at Max Cruise | 6,000 ft (1,800 m) |

| Cruise Speed (600 NM range) | 360 KTAS |

| Cruise Speed (800 NM range) | 310 KTAS |

| Cruise Speed (1200 NM range) | 240 KTAS |

| Range at 310 KTAS | 800 NM (1,481 km) |

| Takeoff Ground Roll (SL, ISA) | 2,035 ft (620 m) |

| Takeoff Distance to 50ft (SL, ISA) | 3,707 ft (1,130 m) |

| Takeoff Distance to 50ft (SL, ISA+25°C) | 3,904 ft (1,190 m) |

| Takeoff Distance to 50ft (SL, ISA+35°C) | 4,003 ft (1,220 m) |

| Landing Field Length (SL, ISA) | 2,493 ft (760 m) |

| Approach Angle Capability | 5.5° |

| Runway Width for 180° Turn | 18 m (59 ft) |

Fuel Consumption and Reserve Requirements

| Flight Profile | Hydrogen Required | Percentage of Total |

| Standard 800 NM Mission | 180 kg | 72% |

| Reserve Fuel | 70 kg | 28% |

| Total Fuel Load | 250 kg | 100% |

| Fuel Consumption Rate (800 NM) | 0.225 kg/NM | - |

| Reserve Requirements | 100 NM + 45 minutes | - |

Cabin and Passenger Configuration

| Feature | Specification |

| Passenger Capacity | 6-8 passengers |

| Crew | 2 pilots |

| Total Occupancy | 8-10 total |

| Seating Configuration | Forward-facing |

| Window Type | Elliptical panoramic |

| Window Size Advantage | 27% larger than standard |

| Noise Reduction | 15 dB(A) reduction |

| Connectivity Option | Starlink Wi-Fi |

| Wi-Fi Speed Range | 40-220 Mbps |

| Connectivity Latency | Ultra-low latency |

Competitive Aircraft Comparison

| Aircraft Model | Country | Propulsion Type | Pax Capacity | Range (NM) | Speed (KTAS) | MTOW (kg) | Development Status | Expected Entry |

| Beyond Aero BYA-1 | France | Hydrogen fuel cell | 6-8 | 800 | 360 | 8,618 | Development/Testing | 2026-2028 |

| Eviation Alice | Israel | Battery electric | 9 | 440 | 250 | 6,350 | First flight completed | 2025-2026 |

| Joby SHy4 Demo | USA | Hydrogen fuel cell | 1 (pilot only) | >500 | 174 | TBD | Tech demonstrator flew | Technology demo only |

| VoltAero Cassio 600 | France | Hybrid (battery + ICE) | 10 | 648 | 200 | <2,500 | Development | 2025-2026 |

| Heart Aerospace ES-30 | Sweden | Hybrid (battery + turbogen) | 30 | 248 (electric only) | TBD | 21,000 | Prototype testing | 2028+ |

| Wright Spirit | USA | Hybrid electric | 100 | Regional | TBD | TBD | Early development | 2030+ |

| ZeroAvia ZA600 | UK/USA | Hydrogen fuel cell | 19 | 350 | 300 | 10,000 | Flight testing | 2025-2026 |

Business Aviation Market Focus Comparison

| Aircraft | Type | Capacity | Range (NM) | Speed (KTAS) | MTOW (lb) | Key Advantage | Market Position |

| BYA-1 | H2 fuel cell | 6-8 | 800 | 310-360 | 19,000 | Long range, zero emissions | Premium business jet |

| Eviation Alice | Battery electric | 9 | 440 | 250 | 14,000 | Mature electric technology | Regional/charter |

| VoltAero Cassio 600 | Hybrid electric | 10 | 648 | 200 | 5,500 | Fuel flexibility | Light business/personal |

| ZeroAvia ZA600 | H2 fuel cell | 19 | 350 | 300 | 22,000 | Proven H2 technology | Regional airline |

The BYA-1's specifications demonstrate significant advantages in the emerging sustainable aviation market. Its 800-nautical-mile range exceeds that of battery-electric competitors by over 80% while maintaining zero-emission operations throughout the entire flight envelope. The aircraft's 360-knot maximum cruise speed positions it competitively against conventional business jets, while its short-field performance enables access to constrained airports that larger aircraft cannot serve.

The hydrogen fuel cell powerplant provides three times the energy density of batteries, enabling the BYA-1’s superior range-to-weight ratio. With 250 kg of hydrogen fuel providing 800 nautical miles of range, the aircraft achieves a fuel consumption of 0.225 kg per nautical mile, establishing new efficiency benchmarks for zero-emission flight operations.